Understanding 3D Holographic Scanning

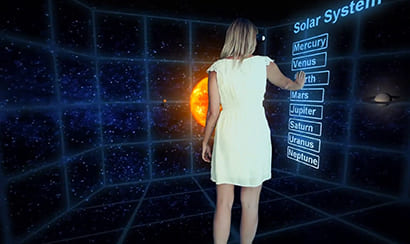

The 3D transparent projector screen method is a technology-driven process of occupying features and physical dimensions of real-world objects to develop appropriate digital presentations. Vision3D includes the usage of specific devices like structured light or laser scanners, which emit patterns or beans onto the object’s surface. The scanner secures the disturbances or the reflections of these beans, developing a point cloud (a group of data points in 3D space). After occupying the point cloud, the software exercises the data to develop an understandable and detailed holographic projection screen. This model can be further filtered via multiple strategies involving texturing and meshing.

The outcome is a digital copy of the scanned object, preserving its surface information and geometry. The 3D scanning applications expand around various industries, The applications of 3D screens span across industries, enveloping regions such as healthcare, manufacturing, entertainment and architecture offering worthy insights and allowing invention in product design, virtual experiences and quality control.